We specialize in the design, manufacturing, and sales of lifting and rigging hardware, such as lifting points and permanent lifting magnets. Since our lifting products play a critical role in our customers' operations, where safety is paramount, we place the utmost importance on quality. This commitment to quality begins with the use of superior raw materials.

Our lifting point products meet the stringent requirements of EN1677-1 standards. To achieve this, we partner with leading steel manufacturers in China to source custom steel agreements. These agreements specify the inclusion of at least 0.025% aluminum (Al) for enhanced material strength and a combination of chromium (Cr), nickel (Ni), and molybdenum (Mo), along with other trace alloying elements.

These measures enhance material properties, ensuring greater resistance to fatigue and improved tensile strength. Compared to standard alloy steel, our custom steel guarantees stable and reliable alloy compositions, undergoes 100% ultrasonic flaw detection to eliminate internal cracks, and maintains a uniform microstructure free from segregation with a finer grain size, optimizing load-bearing capacity and durability under dynamic conditions.

For every product specification and component, we carefully select the most appropriate alloy materials to precisely enhance performance. If you require detailed information about the materials used in specific components, please reach out to our service team for further assistance.

The production process for rotating lifting points involves a series of integrated steps, including cutting, machining, welding, heat treatment, precision machining, surface treatment, and rigorous testing. These steps require specialized production lines and equipment to ensure the precision, strength, and safety of the lifting point products.

With over 20 years of steady development, we have established advanced production lines dedicated to lifting and rigging equipment. These ensure precision, efficiency, and compliance with the stringent safety standards required for lifting point products.

Raw Material Warehouse

Steel cutting machine: Used to cut high-strength alloy steel into the required dimensions (cut-to-length) to ensure precise preparation for subsequent processes

Forging and Welding Workshop

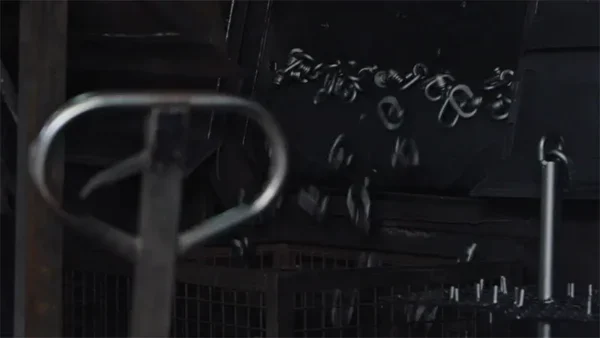

- Automatic forging line: Equipped with forging presses, punching machines, and heating furnaces to handle forging tasks efficiently

- Welding machine: Used for welding components of lifting points, ensuring high welding quality

Machining Workshop

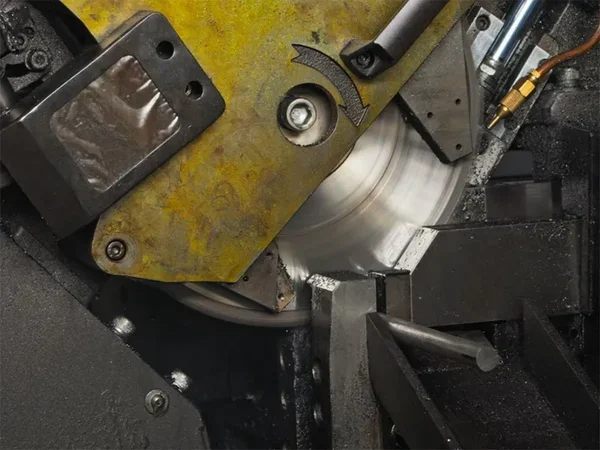

CNC machine tools (lathe, milling machine, vertical/horizontal machining centers): Utilized for precise machining of lifting points, including shaping, threading, and crafting complex structures, ensuring dimensional accuracy and strength requirements

Precision Machining Workshop

- Precision grinding machine: Used for fine grinding of lifting point surfaces to achieve smooth finishes and precise dimensions

- Surface treatment equipment: Applied for anti-corrosion treatments, including blackening, electrophoresis, and Dacromet coating, enhancing corrosion resistance and aesthetic appeal

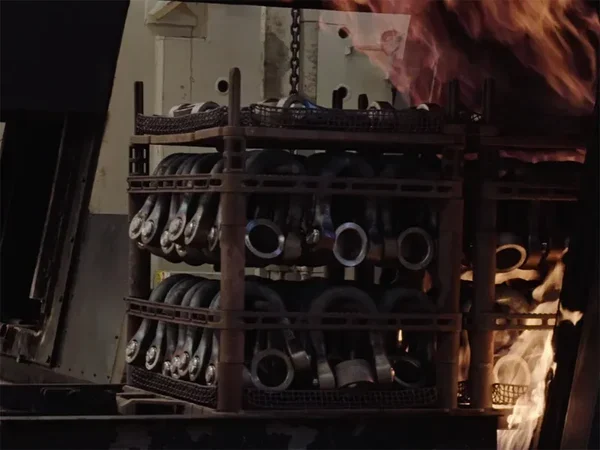

Heat Treatment Workshop

Heat treatment furnace with temperature control system: Used for annealing, normalizing, and quenching lifting points to improve mechanical properties such as hardness and wear resistance

Assembly and Coating Workshop

- Packaging line: Ensures finished lifting points are securely packaged to prevent damage during transportation

- Assembly workbench: Used for assembling and inspecting components of rotating lifting points, ensuring secure connections and smooth rotational functionality

- Spray coating machine: Combines manual and automated operations for efficient powder coating, allowing color customization of lifting points while maintaining orderly production

Semi-Finished Product Warehouse

Inventory management system: Efficiently organizes semi-finished product areas with clear categorization. Provides real-time inventory updates to support production planning effectively