BLT092 Rigging Hardware

Weld-On Load Ring (Lashing Load Ring)

BLT092 Rigging Hardware

Weld-On Load Ring (Lashing Load Ring)

-

Working Load Limit 4-31.5t

- Material: High-strength chromium-molybdenum alloy steel

- Attachment type: Welding

- Pivot angle: 180°

- Surface treatment (rings): Powder-coated

- Working temperature range: -40℃~+200℃

- Chain grade: G80

- Custom thread: Metric/Unified National Coarse (UNC)/ Unified National Fine (UNF)/ pipe thread/ lengthened/ shortened

- Rotates under load: No

- Holding spring for suspension link: No

- Working load limit: 4T-31.5T

- Safety factor: 4:1

- Standard: DIN EN 1677-1

- Explosion protection: No

- RAL color No.: Customizable

- Identification label available: No

Inspection and Standards

- Tested with 1.5x load fatigue cycles (20,000 cycles) and 2.5x rated load tests for exceptional durability

- Inspected using magnetic particle testing to ensure no surface cracks or defects

- Produced in accordance with EN1677-1 standards, with certified test reports available upon request

Applications

- Transportation: Ideal for lifting and transportation of heavy cargo, oversized components and containers, minimizing errors and reducing the risk of collisions or damage.

- Industrial plants: Commonly used for lifting industrial generators, boilers, compressors, and other heavy machinery in factories.

The weld-on load ring is engineered for heavy-duty lifting and anchoring applications, offering a working load limit of 4-31.5t and 180° pivot functionality. Designed for permanent attachment via welding, the lashing load ring creates a stable and secure lifting point ideal for industrial, and oil & gas operations.

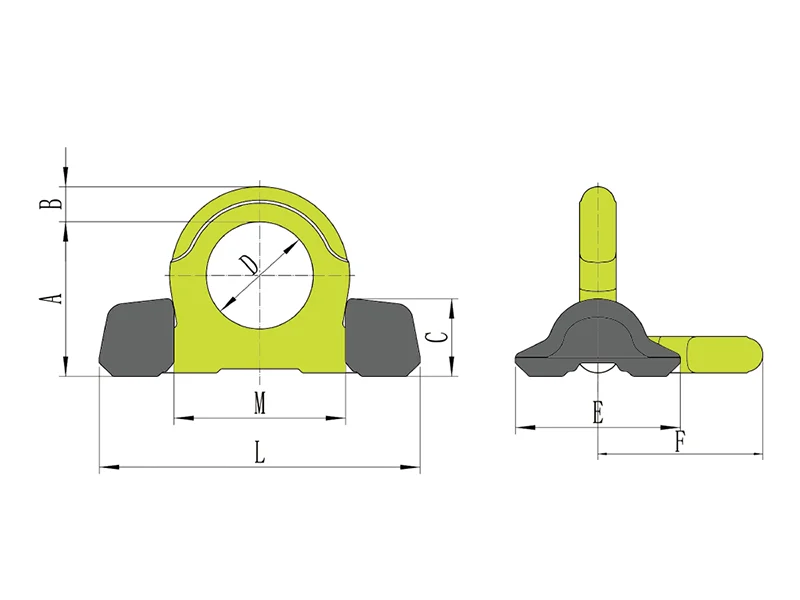

Specifications

| Item No. | Working Load Limit (t) | Dimensions (mm) | Weight (kg) |

| A | B | C | D | E | F | L | M | HV | a |

| BLT092-04 | 4.0 | 66 | 14 | 30 | 48 | 65 | 70 | 135 | 76 | 5 | 3 | 0.6 |

| BLT092-06 | 6.7 | 85 | 20 | 39 | 60 | 89 | 91 | 171 | 98 | 5 | 3 | 1.5 |

| BLT092-10 | 10.0 | 95 | 21 | 46 | 65 | 100 | 100 | 196 | 106 | 7 | 4 | 2.4 |

| BLT092-16 | 16.0 | 127 | 30 | 57 | 90 | 130 | 136 | 263 | 149 | 8 | 4 | 5.5 |

| BLT092-30 | 31.5 | 178 | 42 | 78 | 130 | 160 | 160 | 375 | 213 | 15 | 4 | 15.8 |

* Safety factor of 4:1;

* Welding operations must be carried out by qualified welding personnel in accordance with EN287 or AWS specifications;

Working Load Applications

| Lifting Method |  |  |  |  |  |  |  |  |

| Number of Sling Legs | 1 | 2 | 1 | 2 | 2 | 2 | 3-4 | 3-4 |

| Lifting Angle | 0° | 0° | 90° | 90° | 0-45 | 45-60° | Asymmetry | 0-45 | 45-60° | Asymmetry |

| Item No. | Working Load Limit (t) |

| BLT092-04 | 4.0 | 8.0 | 4.0 | 8.0 | 5.6 | 4.0 | 4.0 | 8.4 | 6.00 | 4.0 |

| BLT092-06 | 6.7 | 13.4 | 6.7 | 13.4 | 9.4 | 6.7 | 6.7 | 14.1 | 10.05 | 6.7 |

| BLT092-10 | 10.0 | 20.0 | 10.0 | 20.0 | 14.0 | 10.0 | 10.0 | 21.0 | 15.00 | 10.0 |

| BLT092-16 | 16.0 | 32.0 | 16.0 | 32.0 | 22.4 | 16.0 | 16.0 | 33.6 | 24.00 | 16.0 |

| BLT092-30 | 31.5 | 63.0 | 31.5 | 63.0 | 44.1 | 31.5 | 31.5 | 66.2 | 47.25 | 31.5 |

Welding Conditions

- The carbon content of the base material must be below 0.4%.

- If the ambient temperature is below 10°C, preheat the surface before welding.

- Welding should not be performed in open areas or under adverse weather conditions.

Welding Methods

- Ensure the contact surface is clean and free from metal shavings, oil, paint, slag, or other contaminants. Corroded or painted surfaces must be completely cleaned of rust and paint before welding.

- Clean the weld seam before proceeding to the next pass to avoid slag inclusions.

- Once welding starts, do not interrupt the process to prevent component cooling.

- Thoroughly inspect the weld points to ensure there are no cracks, dents, or scratches. If concerns arise, use non-destructive inspection methods, such as magnetic particle or dye penetrant testing.

- For repairs, grind out any defects and repeat the welding process with qualified procedures.

- Avoid rapid cooling of the weld points.

-

CustomizeWe offer full customization based on customer requirements, including markings, colors, logos, bolt coating processes, and appearance. We can also design drawings tailored to specific needs.

-

ServiceBoth metric and UNC threaded hoist rings are available in stock and can be shipped within 1–3 days. For special threaded hoist rings, delivery can be arranged within 3–15 days (contact our service team for bulk order confirmation).